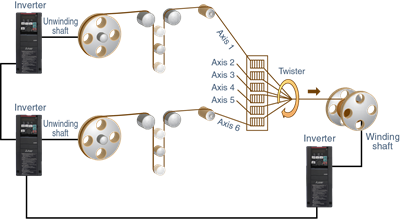

The FR-A800-R2R inverter offers a host of dedicated functions including automatic winding diameter calculations, automatic dancer speed control, and sensorless torque control to perform fast, smooth, and accurate winding and unwinding applications. These complex functions do not require additional sequence or motion control programming to implement because the FR-A800-R2R inverter has a built-in PLC, eliminating the need for a separate controller, and utilizes easy-to-use parameterization to set and enhance functions. Even without advanced knowledge of tension control, users can control winding/unwinding (roll-to-roll) easily with the dedicated functions.

Key Benefits

Speed Control and Gain Compensation – PID control utilizes the feedback from the detected dancer roll position or feedback from the tension sensor. Stable control can be achieved in combination with the winding diameter calculation. By adjusting the speed control proportional gain according to the winding diameter, the response level can be kept constant. The actual response level corrections along with the changes in the inertia ratio of the winding and unwinding shafts in order to improve the tracking ability to allow for the changes in the diameter.

Speed Control and Gain Compensation – PID control utilizes the feedback from the detected dancer roll position or feedback from the tension sensor. Stable control can be achieved in combination with the winding diameter calculation. By adjusting the speed control proportional gain according to the winding diameter, the response level can be kept constant. The actual response level corrections along with the changes in the inertia ratio of the winding and unwinding shafts in order to improve the tracking ability to allow for the changes in the diameter.Contact us to discuss your Wind/Unwind Application needs

Copyright © 2022 · All Rights Reserved ·

Clayton Controls Inc. - Headquarters, 2865 Pullman Street, Santa Ana, CA 92705 Tel: 800-235-4411

Campbell Office, 1671 Dell Ave., Suite 110, Campbell, CA 95008 Tel: 800-341-4445

Central California Office, 109 Fox Street, Lemoore, CA 93245 Tel: 800-235-4411

Arizona/Southern Nevada Office, 4343 N. Scottsdale Road, Suite 150, Scottsdale, AZ 85252 Tel: 480-673-3327